Tuur baararka shabagagga birta ah, ku xir qaybo ka mid ah qashinka foornada tamarta

1. Qaabka ridaya: Shell cast cast sax

2. Darajada birta: GX130CrSi29 (1.4777) (Sidoo kale waxay noqon kartaa sida looga baahan yahay)

3. Dulqaadka cabbir ahaan: DIN EN ISO 8062-3 fasalka DCTG8

4. Dulqaadka joomatari ee kabka: DIN EN ISO 8062 - fasalka GCTG 5

5. Codsiga: Qashinka dhirta lagu gubo tamarta.

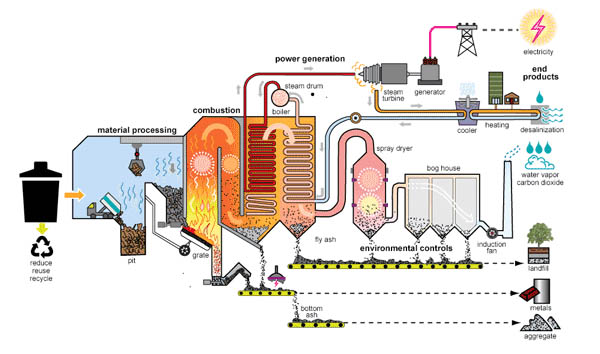

Qaadista qashinka hadda waa dhibaato caalami ah oo aad u daran. Qashinka tamarta ayaa ah daaweynta ugu macquulsan waqtigaan la joogo. Sanadihii la soo dhaafay, dalal badan oo leh awood dhaqaale oo xoog leh ayaa bilaabay inay fiiro gaar ah u yeeshaan qodobkaan. Lacag aad u tiro badan ayaa lagu maal geliyey dhismaha warshadaha tamarta qashinka lagu gubo. Tani kaliya kuma soo kordhin horumar weyn deegaankeena. Isla markaana, waxay inoo keentay faa iidooyin dhaqaale oo aad u badan.

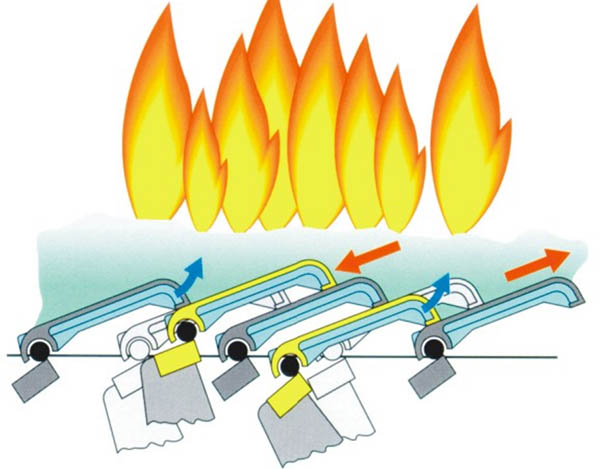

Sida ku cad jaantuska, baararka jajabku waxay door muhiim ah ka ciyaaraan gubista qashinka. Heerkulka sare iyo jawiga aadka u qalafsan, shabagga tayada hooseeya wuxuu si weyn u saameyn doonaa hufnaanta qashinka lagu gubo, nolosha adeeggeeduna aad ayey u gaaban tahay Waxaad u baahan tahay inaad badasho badiyaa.

Si kastaba ha noqotee, in ka badan 10 sano oo aan khibrad u leenahay, waxaan kuu xallin karnaa dhibaatooyinka adiga.

Fasalka Birta ah ee aan inta badan isticmaalno. (Waxay kaloo noqon kartaa shuruudahaaga.)

Halabuurka kiimikada% ee birta GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

ugu badnaan 1 |

ugu badnaan 0.035 |

ugu badnaan 0.03 |

27 - 30 |

ugu badnaan 0.5 |

Waxyaabaha kiimikada% ee birta GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0,5 |

1 - 2.5 |

ugu badnaan 1.5 |

3 - 6 |

ugu badnaan 0.04 |

ugu badnaan 0.03 |

25 - 28 |

ugu badnaan 0.5 |

Waxyaabaha kiimikada% ee birta GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0,5 |

1 - 2.5 |

ugu badnaan 2 |

19 - 22 |

ugu badnaan 0.04 |

ugu badnaan 0.03 |

24 - 27 |

ugu badnaan 0.5 |

Waxyaabaha kiimikada% ee birta GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0,5 |

1 - 2.5 |

ugu badnaan 2 |

11 - 14 |

ugu badnaan 0.04 |

ugu badnaan 0.03 |

24 - 27 |

ugu badnaan 0.5 |

| Guryaha farsamada (ASTM A297 Fasalka HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Dheereynta: 2 ee: Min 10% | |

| Engegnaantiinna: Min 200 BHN (3 meelood oo mala awaal ah) " | |

| Microstructure / Metallography | Qaabdhismeedka Austenitic-ku u badan ee ay kujiraan carbideska lakala firdhiyey |

| Tijaabada 'SoundnessTest / X-ray ama UT | RT halkii ASTM E446 Heerka II |

| UT halkii ASTM A609 Heerka II | |

| NDT / LPI ama MPI | MPI sida ku cad ASTM E709 / E125 HEER II |

| LPI sida ku xusan ASTM E165 Heerka II " | |

| Kormeerka Muuqaalka Ugu Dambeeya | ASTM A802 Heerka II |

| Xirmo | Kiis bir ah ama kiiska looxa. |

Suuqeena Weyn Waa

OEMs iyo shirkadaha injineernimada

Qashinka dhirta Tamarta

Shirkadaha shaqeeya

Qaybaha Biomass

Warshadaha korontada ku shaqeeya ee dhuxul dhagaxa ah

Shirkadaha adeegga ee howlaha dayactirka

Noocyada kala duwan ee OEM baararka shabaggeedii

Si fiican u dhammeeyey baararka shabaggeedii

Habka Bisaylka iyo Xakamaynta Tayada Adag Maxaad noo dooranaysaa

Wixii weydiimo dheeraad ah ama su'aalo farsamo ah, fadlan la xiriir XTJ Service Team. Waxaan ku siin doonaa xalka ugu macquulsan farsamo iyo oraah ugu fiican sida ay sheygaaga.